Walk into any factory, manufacturing plant, or industrial facility, and you’ll find industrial switchgear quietly doing one of the most critical jobs in the building. It controls, protects, and isolates electrical equipment, ensuring power flows exactly where it needs to go.

But here’s the thing about industrial switchgear: it only works reliably when it’s properly maintained. Skip the maintenance, and you’re looking at unexpected breakdowns, production losses, safety hazards, and repair bills that could have been avoided.

Let’s talk about how to keep your industrial switchgear running smoothly for years to come.

Why Industrial Switchgear Maintenance Actually Matters

Industrial switchgear isn’t something you can just install and forget about. These systems operate in demanding environments. They handle high voltages, switch heavy loads, and often work around the clock in conditions that would challenge any electrical equipment.

Over time, connections loosen. Contacts wear down. Dust accumulates. Insulation degrades. Without regular maintenance, small issues that could have been fixed easily turn into major failures that shut down your entire operation.

The cost of maintenance is nothing compared to the cost of downtime. When your production line stops because of switchgear failure, you’re not just paying for repairs. You’re losing revenue, missing deadlines, and potentially damaging your reputation with customers.

Companies like Eurogrid understand this reality. That’s why their industrial switchgear is designed not just for performance, but for maintainability. Good equipment paired with good maintenance practices gives you the reliability industrial operations demand.

Understanding Your Industrial Switchgear

Before we dive into maintenance tips, it helps to understand what you’re maintaining.

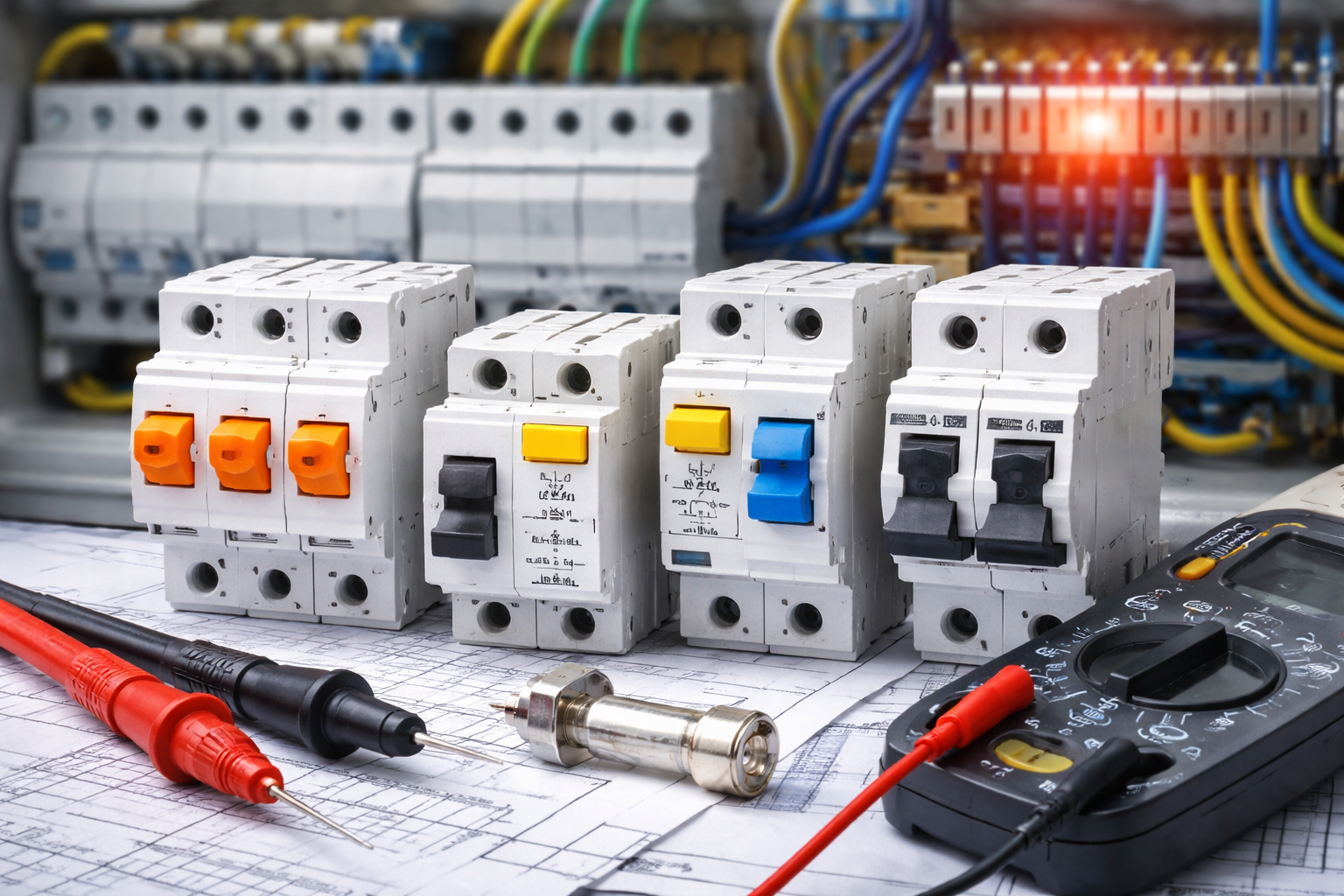

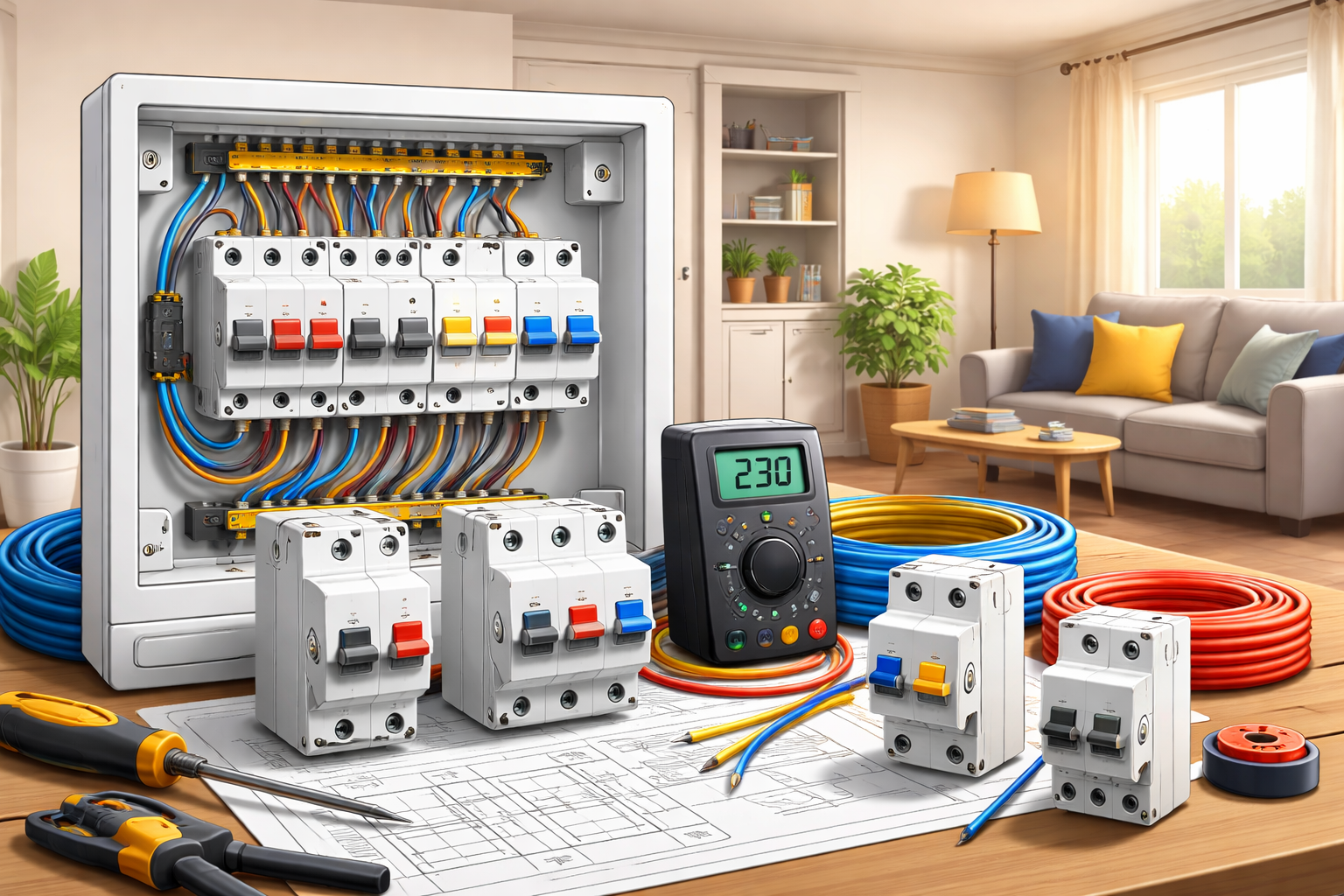

Industrial switchgear typically includes circuit breakers, disconnect switches, fuses, relays, control panels, and bus bars, all housed together in metal enclosures. These components work together to control power distribution, protect against faults, and allow safe isolation of equipment for maintenance.

Different facilities use different types. Low voltage switchgear handles circuits up to 1000V. Medium voltage systems work with 1kV to 36kV. The type you have determines some of your maintenance requirements, but the basic principles remain the same.

Daily and Weekly Checks That Prevent Big Problems

The best maintenance strategy starts with regular observation. Train your operators and maintenance staff to notice changes before they become failures.

Listen for unusual sounds. Humming, buzzing, or crackling noises from your industrial switchgear often signal loose connections, arcing, or failing components. Normal switchgear operates quietly. If it starts making noise, investigate immediately.

Watch for visual warning signs. Discolouration around terminals suggests overheating. Burn marks indicate arcing. Any visible damage to insulation, cables, or enclosures needs attention right away.

Check indicator lights and displays. Many modern switchgear systems, including those from Eurogrid, have built-in diagnostics. Pay attention to what they’re telling you. A warning light is trying to prevent a breakdown.

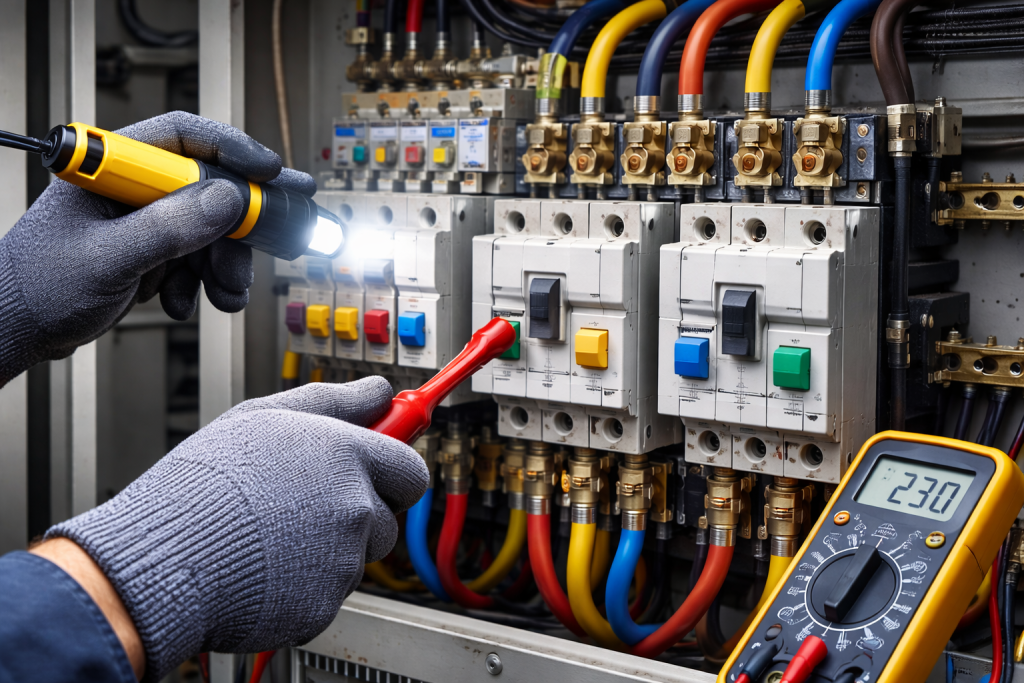

Monitor operating temperatures. Hot spots often develop before failures occur. Infrared thermography during inspections can catch these issues early. If something feels hotter than usual, find out why.

These simple checks take minutes but can save you from hours or days of unplanned downtime.

Monthly Maintenance Tasks

Once a month, schedule time for more thorough inspections of your industrial switchgear.

Clean the enclosures. Dust and debris are enemies of electrical equipment. They trap heat, create paths for electrical tracking, and can cause shorts. Keep your switchgear clean, especially in dusty industrial environments. Use appropriate cleaning methods that won’t damage components or create static electricity.

Inspect all connections. Check terminals, bus bars, and cable connections for tightness. Vibration from nearby machinery can gradually loosen connections, creating resistance and heat. Use a torque wrench to verify that the connections meet the manufacturer’s specifications.

Look for signs of moisture. Water and electricity don’t mix. Check for condensation inside enclosures, especially in facilities with temperature fluctuations or high humidity. If you find moisture, identify the source and fix it before it causes corrosion or tracking.

Test mechanical operations. Manually operate disconnect switches and other mechanical components to ensure they move smoothly. Stiff or sticky operation suggests the need for lubrication or adjustment.

Document what you find. Keep records of your inspections. Patterns often emerge over time that can help you predict and prevent failures.

Quarterly and Annual Inspections

Some maintenance tasks don’t need to happen every month, but they’re still essential.

Thermographic surveys should be performed at least quarterly on critical industrial switchgear. Thermal imaging cameras reveal hot spots invisible to the naked eye. A connection running 20 degrees hotter than it should is a failure waiting to happen.

Contact inspection and cleaning requires more time and often means de-energizing equipment. Circuit breaker contacts wear down over time from arcing during normal operation. Inspect them for pitting, erosion, or discoloration. Clean them according to manufacturer recommendations. Eurogrid provides detailed guidelines for maintaining their switchgear contacts to ensure long service life.

Insulation testing verifies that insulation resistance remains within acceptable limits. Degraded insulation can lead to ground faults or phase-to-phase faults. Use a megohmmeter to test insulation resistance annually, or more frequently in harsh environments.

Protective relay testing ensures that your protection systems will actually protect when needed. Relays should be tested and calibrated according to manufacturer specifications. If your relays don’t operate correctly during a fault, your expensive equipment pays the price.

Lubrication of moving parts keeps mechanisms operating smoothly. Use only the lubricants specified by the manufacturer. The wrong lubricant can attract dust, break down under heat, or damage components.

Handling Repairs and Component Replacement

Even with excellent maintenance, components eventually wear out. The key is replacing them before they fail catastrophically.

Keep critical spares on hand. For essential industrial switchgear, having spare circuit breakers, fuses, control components, and other parts readily available minimizes downtime when replacements are needed.

Use genuine replacement parts. It’s tempting to save money with cheaper alternatives, but components that don’t meet the original specifications can compromise the entire system. When you’re maintaining Eurogrid industrial switchgear, using Eurogrid replacement parts ensures compatibility and reliability.

Don’t ignore small issues. A slightly pitted contact, a marginally loose connection, or a relay that’s just a bit slow might seem like things you can live with. But in industrial environments, these small issues compound. Fix them while they’re still small.

Know when to call in experts. Some maintenance tasks require specialized knowledge, equipment, or safety procedures. Medium voltage switchgear maintenance, in particular, should only be performed by qualified personnel with proper training and safety equipment.

Safety First, Always

Maintaining industrial switchgear involves working around high voltage and high current. Safety isn’t just a suggestion. It’s an absolute requirement.

Follow lockout/tagout procedures religiously. Before working on any switchgear, ensure it’s properly de-energized, locked out, and tagged. Verify the absence of voltage with appropriate testing equipment. Assume nothing.

Use proper personal protective equipment. Arc-rated clothing, insulated gloves, safety glasses, and other PPE appropriate to the voltage level you’re working with aren’t optional. They’re essential.

Maintain safe approach distances. Even de-energized equipment can have stored energy in capacitors or backfeed from other sources. Know the safe distances for the voltage levels you’re dealing with.

Never work alone on high-risk tasks. Having a second person present during switchgear maintenance isn’t just smart. It could save your life if something goes wrong.

Eurogrid emphasizes safety in all their technical documentation and training materials, recognizing that proper maintenance practices and worker safety go hand in hand.

Creating a Maintenance Schedule That Works

The best maintenance program is one that actually gets followed. Here’s how to build a sustainable schedule:

Start with manufacturer recommendations. The people who built your industrial switchgear know what it needs. Follow their maintenance guidelines as your baseline.

Adjust for your operating conditions. A facility running three shifts in a corrosive environment needs more frequent maintenance than one operating eight hours a day in a clean room. Tailor your schedule to your reality.

Use condition-based maintenance when possible. Rather than just maintaining on a fixed schedule, monitor actual equipment condition. Modern switchgear with diagnostic capabilities makes this easier than ever.

Plan maintenance during scheduled downtime. Coordinate switchgear maintenance with production schedules to minimize disruption. Unexpected maintenance is always more expensive and disruptive than planned maintenance.

Keep detailed records. Track what was done, when, by whom, and what was found. This history helps you optimize your maintenance program and catch trends before they become problems.

The Long-Term Payoff of Proper Maintenance

Good maintenance of industrial switchgear isn’t just about avoiding breakdowns. It’s about maximizing the return on your investment in electrical infrastructure.

Well-maintained switchgear lasts longer. Components that are kept clean, tight, and properly adjusted can serve reliably for decades rather than years.

Energy efficiency improves too. Loose connections create resistance, which wastes energy as heat. Properly maintained switchgear operates more efficiently, reducing your energy costs.

Safety improves dramatically. Most switchgear failures that result in injuries or fires could have been prevented with proper maintenance. You’re not just protecting equipment. You’re protecting people.

And when it does come time to upgrade or expand, well-maintained equipment has better resale or trade-in value. It demonstrates that your facility takes its infrastructure seriously.

Why Choose Quality Industrial Switchgear

Maintenance matters, but it starts with quality equipment. Eurogrid’s industrial switchgear is engineered for reliability and designed for maintainability. Their products include features that make inspection easier, components that are built to last, and comprehensive documentation that helps maintenance teams do their jobs effectively.

When you invest in quality industrial switchgear from the start, you’re setting yourself up for lower long-term maintenance costs and higher reliability. Cheap equipment might save money initially, but it costs more over its lifetime in maintenance, repairs, and downtime.

Final Thoughts

Industrial switchgear is the backbone of your facility’s electrical system. Like any backbone, it needs care and attention to stay strong.

The maintenance tips covered here aren’t complicated or exotic. They’re practical, proven practices that keep industrial switchgear running reliably year after year. The investment of time and resources in regular maintenance pays dividends in uptime, safety, and equipment longevity.

Whether you’re managing a small manufacturing facility or a large industrial complex, making switchgear maintenance a priority protects your operations, your people, and your bottom line.

And when you combine quality equipment like Eurogrid industrial switchgear with disciplined maintenance practices, you get the reliable performance that modern industry demands.